Laboratories – Mechanical Engineering

1. Mechanical Measurements and Metrology:

Mechanical Measurements and Metrology Laboratory is designed for measuring and gauging instruments for inspection of precision linear, geometric forms, angular and surface finish measurements. It provides knowledge and training of measurement principles to the students by measuring different dimensions using fundamentals of arithmetic, geometry, trigonometry and algebra concepts with the help of instruments such as different types of vernier calipers and micrometers, vernier height gauge, vernier depth gauge, slip gauges, sine bar, vernier bevel protractor, gear tooth vernier caliper, dial indicator etc.

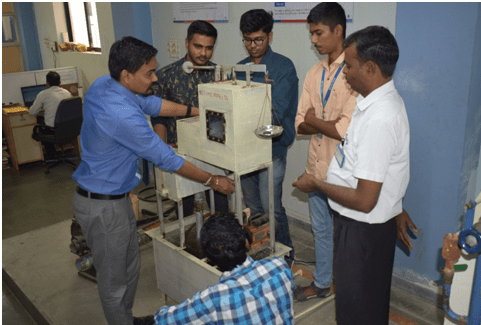

2. Fluid Mechanics

The Fluid Mechanics laboratory is actively engaged to reinforce and enhance understanding of the fundamentals of Fluid Mechanics. The experiments here are designed to demonstrate the applications of the basic fluid engineering principles and to provide a more intuitive and physical Understanding of the theory. The laboratory runs closely with the lectures in such a way that experiments support the text covered in the class room At Present the laboratory is equipped with various stand alone setups to carry out experiments like verification of Bernoulli’s energy equation, determination of Metacentric height of ship model, determination of coefficient of discharge for obstruction flow meters (Venturimeter and Orifice meter), determination of coefficient of discharge and coefficient of velocity for Orifice and Mouthpiece, determination of coefficient of discharge for various Notches, determination of friction coefficient for different pipes and determination of loss coefficient for various pipe fittings. The laboratory also houses Reynolds apparatus to visualize different flow patterns and free and forced vortex apparatus to understand the vortex motion of the fluid.

3. Manufacturing Processes

Manufacturing processes related to machining are included in this subject. All conventional manufacturing machines like lathe machine, drilling machines, milling machine, shaper machine, slotting machine are included in this course to understand the basic concepts in machining science. Individual student will perform different opertations on different machine and will get basic idea of manufacturing.

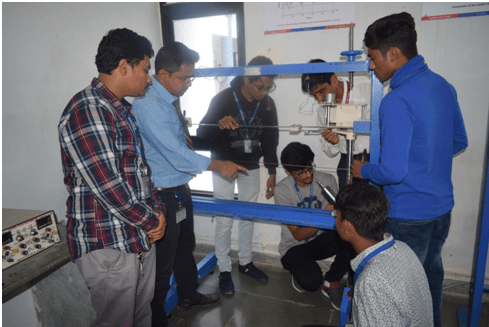

4. Dynamics Of Machine

Dynamics of machine laboratory have great significance in the study of those machines where unbalance forces play a critical role. To understand the effect of unbalance forces on the machines and to reduce their effects, the dynamics of machine lab under the department is equipped with some essential experimental setups such as static and dynamic balancing apparatus, balancing of reciprocating masses apparatus, longitudinal, transverse and torsional vibration apparatus, forced vibration apparatus, double rotor shaft system apparatus, whirling of shaft apparatus etc.

5. Internal Combustion Engineering

The IC engine lab of mechanical department is one of the exquisite lab which comprises of several apparatus along with motorised models of petrol and diesel engine. Performance and testing setup of SI and CI engine helps the students to optimize the parameters by means of which power output and thermal efficiency can be enhanced. It also provides the facility for the students to carry out the research at various levels in the IC engine field.

6. Refrigeration and Air-Conditioning

Refrigeration and Air-conditioning laboratory aims to provide the fundamental knowledge regarding the types of refrigeration, refrigeration cycles, refrigerants, air-conditioning processes and air-conditioning systems. The laboratory is equipped with experimental set-ups like Vapour compression refrigeration system, Heat pump trainer, Vapour absorption refrigeration system (Electrolux refrigerator), Air-conditioning process demonstrator and Gas charging station. The laboratory also has Cut-sectional of refrigeration control and accessories. Various experiments such as: determination of COP of vapour compression refrigeration system, heat pump, electrolux refrigerator; and to perform various psychrometric process are performed.

7. Production Technology

Production Technology Laboratory is a place whereby the students are able to carry out hands-on practise, analyse the effects of the machining parameters, Thermal effects on the tool materials that they learn in the classroom. The laboratory has the facilities to understand the Metal cutting process, carrying out cutting force calculations, study related to Non Conventional Machining Processes (EDM), designing of Jigs and Fixtures, study of different types of Presses that are demonstrated so as to avail clarity of the principles and processes.

8. Automobile Engineering

The lab is well-equipped and enables students to understand the fundamentals of Automotive Engineering which includes basic structure, body style, transmission &driveline system, suspension system, steering mechanism, braking system, propeller shaft and differential and wheel & tyre assembly.

Major Equipment in Automobile Engineering Lab are:- Chassis of an automobile, Gearbox, Hydraulic and Mechanical brake, Vehicle lighting system, Wheel and tyre assembly, Wind screen and Clutches.

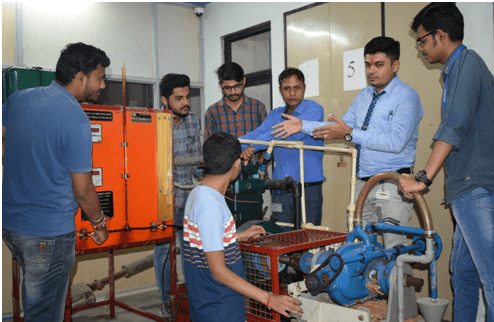

9. Fluid Power Engineering

The Fluid Power Laboratory is where the students put into practice the principles of hydraulic machine design that they learn in the classroom. This Laboratory has facility to introduce Flow through Pipes, Impact of Jet, Hydraulic Turbines, Pumps, Different Compressors and Miscellaneous Machines. The specific objectives of this laboratory course are to provide the student with an opportunity to explore the fundamental principles of fluid mechanics through experimentation, demonstrate and analyze key hydraulic phenomena using hands-on physical devices

10. Computer Aided Manufacturing

Computer Aided Manufacturing is highly demanded area now a day. Computer Aided Manufacturing deals with Design of components to manufacturing and also includes Planning and controlling the processes. Industries widely use CNC, FMS and Robotics technology now a day. Students will be familiar with its hardware and software and also able to write programs for machining. In this subject Students will describe basic concepts of CAM application and understand CAM wheel, prepare CNC programs for manufacturing of different geometries on milling, lathe, drilling machines, prepare logic diagram for different application of automation, classify different components using different techniques of group technology, prepare Process planning for different component, studying different layouts of FMS for industrial applications, describe Robot for preliminary industrial applications like pick and place, identify application of PPC, JIT, MRP-I, MRP-II, and Expert system to

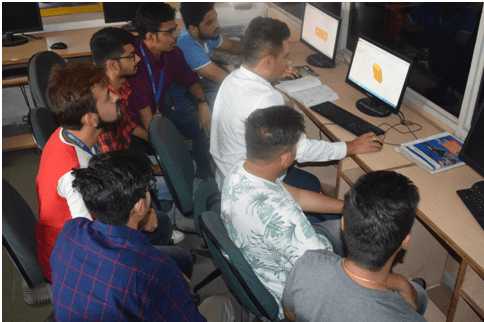

11. Software (Computer Aided Design)

Computers are extensively used in various stages of product design and development process. This field is broadly termed as Computer Aided Design (CAD). This subject introduces students to the modern tools and techniques used at product design conceptualization, modeling and analysis phases. The CAD laboratory of Mechanical Engineering department is equipped with following facilities and software: High configuration computers (25 Nos), Creo 4.0 (PTC) : 3D modeling, designing and analysis software, AutoCAD: Drafting and modelling software, Programming with C and C++

12.Machine Design

Machine design occupies a prominent position in the curriculum of Mechanical Engineering. It consists of applications of scientific principles, technical information and innovative ideas for the development of a new or improved product. The Machine design laboratory includes the innovative mechanical component design like, Design of Gears & Gear boxes, Design of Bearings, Design of I.C Engine Components and Design of material handling equipment. The design tools are used to help companies for rapid development of high quality new products.

13.Heat Transfer

Heat transfer laboratory provides fundamental knowledge about all the three modes of heat transfer (Conduction, Convection and Radiation) and their application. The laboratory is equipped with experimental test rigs targeted for undergraduate heat transfer course. Experimental setups available to understand the basics of Conduction heat transfer include: composite wall apparatus, conductivity measurement apparatus, guarded hot plate apparatus, lagged pipe apparatus and unsteady state heat transfer apparatus. The laboratory also houses free and forced convection apparatus to demonstrate convection heat transfer processes and Stephen Boltzmann apparatus and emissivity measurement apparatus to understand Radiation heat transfer process. The lab is also equipped with some setups which are based on application of heat transfer like: parallel and counter flow heat exchanger, shell and tube heat exchanger, drop and film wise condensation apparatus and critical heat flux apparatus.

14. Fundamental of Machine Design

Fundamentals of Machine design lab focuses on the basic principles of the following three areas: Mechanical behavior includes statics, dynamics, strength of materials and fatigue. Detail and Assembly Drawing of Machine elements like Cotter Joints, Knuckle Joints, Levers, Screw Jack, etc. Manufacturing Considerations include areas such as material selection, manufacturing considerations for various manufacturing processes, engineering statistics, aesthetics and ergonomics, and life cycle analysis. Software related to Fundamentals of Machine Design Lab which is available in CAD lab: Total Number of Computers: 20 Technical Software available in the lab: Autocad

15. Engineering Graphics & Design

Engineering Graphics & Design is a language of Engineers for engineering activity. It provides the graphical or pictorial solution of engineering problems. Engineering ideas are recorded by preparing drawings and execution of work is also carried out on basis of drawings. Engineering Graphics Laboratory provides the knowledge of Dimensioning, Scales, Engineering Curves, Projections of lines, plane, solids and Development of lateral surfaces.

16. Material Science and Metallurgy

The knowledge of materials is of utmost important in designing, fabrication and modification of components. To get well acquainted with materials various practical setup are available in lab, like Various Metallurgical microscopes for studying microstructure of materials, Double disc polishing machine and hot mounting press to prepare sample for microstructural study, muffle furnace to carry out various heat treatments, Jominy hardenability test rig, facility Non- destructive testing facility DPT and Ultrasonic testing

17. WORKSHOP

The study of workshop practice acts as the basis for further technical studies. Workshop practices are included in the curriculum in order to provide hands on experience about the use of different engineering materials, tools, equipments and processes that are common in engineering field. The Institute has a modern well established workshop, equipped with various traditional as well as most modern machines and latest tools and instruments. It imparts basic knowledge of various tools and their use in different sections of manufacture such as Fitting, Welding, Carpentry, Smithy, Machine , Plumbing and sheet metal Shop etc.